Pressure Vessels

Pressure vessels are steel tanks used to receive, store and release gases or liquids under pressure significantly different from atmospheric. They are an important link in the technological chain in the production, processing and storage of petroleum products, gases, chemicals and food products.

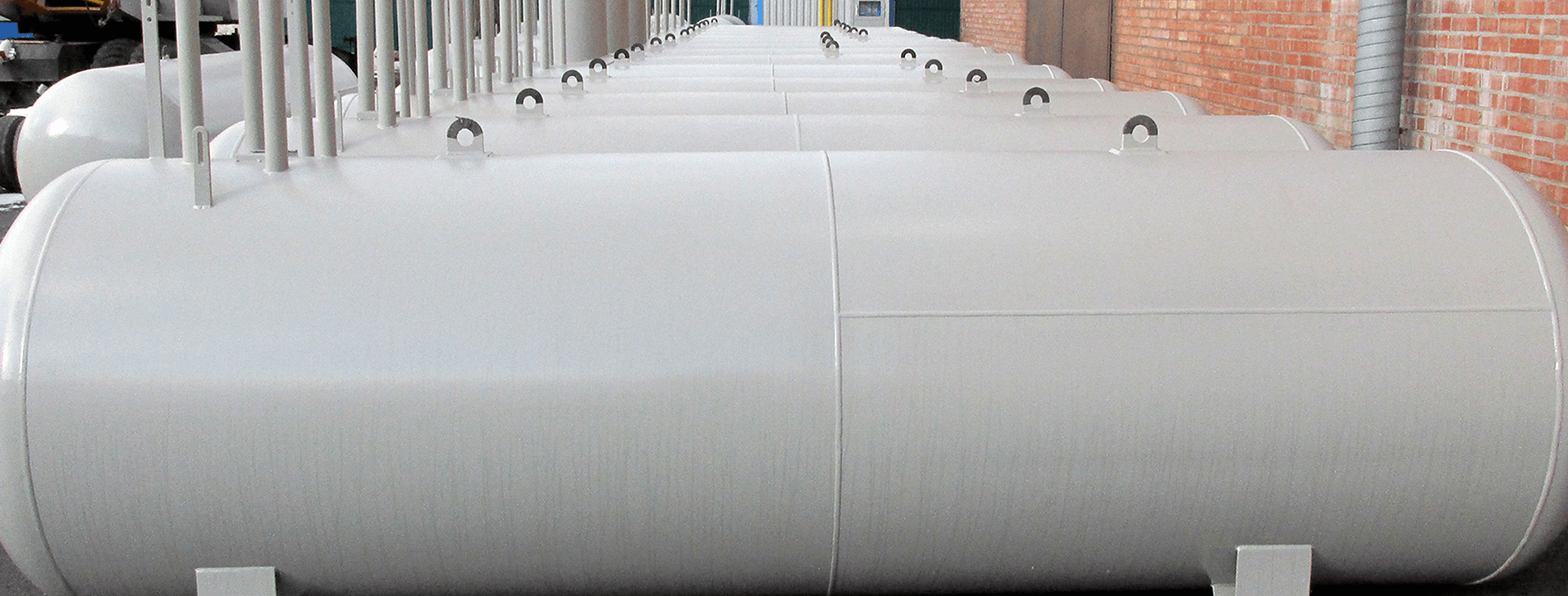

We produce cylindrical welded steel vessels. Orientation can be horizontal or vertical. Body - all-welded or detachable. Our pressure vessels are delivered to the site of operation in full factory readiness. Installation is carried out on supports-paws or supports-racks.

Industrial pressure vessels are technical devices, the operation of which makes the production facility dangerous. A large number of accidents are associated with pressure vessel accidents, therefore their design, construction, manufacture, installation, commissioning, technical diagnostics and operation are strictly controlled. Any defect or error can lead to irreversible consequences:

• thermal or chemical explosions that may occur as a result of depressurization or damage to the strength of equipment;

• poisoning;

• thermal burns.

Therefore, in the production of pressure vessels, we apply increased control measures for welded joints and incoming material control. A leak test at maximum pressure is mandatory.

To control the work and ensure safe operating conditions, the vessels, depending on the purpose, must be equipped with:

• shut-off and control valves;

• instruments for measuring pressure;

• instruments for measuring temperature;

• safety devices;

• level indicators of the stored product

• heaters (inner or outer jacket), if the vessel is operated at a temperature below the freezing point of the stored product.

Pressure vessels come in a wide variety of designs and types. It depends on the technological process within which this equipment operates.

The most commonly used types of pressure vessels are gas storage tanks for hydrocarbon gases (LPG tanks), gas separators, absorbers and industrial receivers.

LPG tanks

LPG tanks are containers designed to store hydrocarbon gas in a liquefied state. This equipment is used at gas processing plants, chemical, agricultural, food, oil and gas enterprises, gas stations, as well as for autonomous gas supply to residential buildings and industrial facilities.

LPG tanks are containers designed to store hydrocarbon gas in a liquefied state. This equipment is used at gas processing plants, chemical, agricultural, food, oil and gas enterprises, gas stations, as well as for autonomous gas supply to residential buildings and industrial facilities.

By design, gas tanks are a single-walled or double-walled all-welded cylindrical vessel with elliptical bottoms on two or more supports. The all-welded design allows transporting the equipment to the place of operation in full factory readiness. In the body of the tank, a technological hatch is provided for inspecting the inner surface and fittings.

Gas tanks can be produced for underground installation. In such cases, elongated necks and waterproofing are provided. Additionally, at the request of the Customer, LPG tanks can be equipped with stairs, platforms, thermal insulation.

It is also possible to manufacture double-walled vessels for liquefied gas, or so-called "vessels-in-vessel". In them, the space between the walls is filled with liquid or nitrogen for additional protection against emergencies and leakage of the stored product.

Gas separators

Gas separators are containers in which gases are filtered and cleaned from various undesirable liquid impurities. They have found the widest application in technological installations for oil and gas processing, as well as in the preparation of gas for transportation and storage.

Gas separators are containers in which gases are filtered and cleaned from various undesirable liquid impurities. They have found the widest application in technological installations for oil and gas processing, as well as in the preparation of gas for transportation and storage.

Regardless of the type, a coagulator and a mesh nozzle are installed inside the gas separator, which ensure the settling of fine fractions, as well as a coil. The parameters of the filter element largely determine the efficiency of the separator: the use of meshes with a large number of sections and additional protrusions contributes to the rapid and efficient removal of liquid impurities from the working environment.

The principle of operation of gas separators is based on the difference in the aggregate states of carbon substances. The gas-liquid mixture to be cleaned is fed into the central part of the gas separator, after which it passes through a mesh packing and is concentrated in the upper part of the vessel. The separated liquid fractions are collected at the bottom of the installation, from where they are removed through a special fitting as they accumulate.

Absorbers

Adsorbers are devices used for drying, purifying or separating vapor, gaseous and liquid products by the surface of a solid or liquid absorber.

Adsorbers are devices used for drying, purifying or separating vapor, gaseous and liquid products by the surface of a solid or liquid absorber.

The design of these devices is a vertical or horizontal cylindrical container on supports, equipped with fittings for the inlet and outlet of the product, as well as hatches or a removable cover for backfilling or replacing the adsorbent layer.

The principle of operation is based on the supply of the treated substance through the inlet fitting, passing through the absorber and output through the outlet pipe.

The volume and type of these devices is selected individually, depending on the task.

Industrial receivers

Receivers are designed to work in tandem with compressors of various types. Their main purpose is to create the necessary supply of air or other gas to smooth out pulsations in the gas pipeline during compressor operation and ensure a uniform flow.

Receivers are designed to work in tandem with compressors of various types. Their main purpose is to create the necessary supply of air or other gas to smooth out pulsations in the gas pipeline during compressor operation and ensure a uniform flow.

Gas receivers can be equipped with shut-off and safety fittings (safety valve, three-way valve, pressure gauge, condensate drain valve, etc.)

The main structural material in the production of industrial receivers is carbon or stainless steel. Design pressure 0.5 - 4.0 MPa.