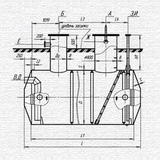

Underground Drainage Tanks

Content:

EuroTankWorks produces underground drainage tanks with and without heating-up.

The underground drainage tanks are used for storing the residues of hazardous liquid products and oil products (both light and dark) discarded from the technological pipelines. These tanks are widely applied at Russian enterprises because almost every production facility faces the necessity to discard the rest of fluid products, used in the technology cycle.

You can choose for yourself a drainage tank of suitable capacity from our standard designs, or order us an individual design.

-

Underground Drainage Tank Vol.5m³ (UDT-5) -

Underground Drainage Tank Vol.8m³ (UDT-8) -

Underground Drainage Tank Vol.12.5m³ (UDT-12.5) -

Underground Drainage Tank Vol.16m³ (UDT-16) -

Underground Drainage Tank Vol.20m³ (UDT-20) -

Underground Drainage Tank Vol.25m³ (UDT-25) -

Underground Drainage Tank Vol.40m³ (UDT-40) -

Underground Drainage Tank Vol.63m³ (UDT-63)

_160x160_539.jpg)