Steel Tanks Fabrication

Silos and storage tanks manufacturer - EuroTankWorks is the up-to-date fabricator of:

- Vertical steel tanks of 100 m³ to 50’000 m³ loading capacity;

- Horizontal steel tanks;

- Drainage storage tanks;

- Silos for bulk stock storage;

Silos and storage tanks manufacturer - EuroTankWorks is the up-to-date fabricator of:

Our workshop Is equipped with a line for processing the edges of sheet metal by milling. The line belongs to the category of key equipment for the steel tank fabrication and is used for sheet metal preparation for welding.

It consists of two machines: longitudinally edge-milling machine (for processing steel plates in width) and transverse end-milling (for processing ends of steel plates, i.e. processing in length).

The processing is done by the simultaneously milling of the edges of the metal plates along their length. As a result, its accurate design size is achieved in width as well as the correct geometric shape. Parallel milling allows to process metal 3-4 times faster than, for example, on a conventional planer.

Not all storage tanks manufacturers have such equipment. Therefore, the sheet metal edge milling line is one of our competitive advantages.

EuroTankWorks JSC is one of the few storage tanks and silos manufacturers in the world equipped with the special coiling machine. This enables to produce coiled panels of the wall, bottom and roof of the tank with the use of automated double-welding.

First, a map of the panel is collected on the upper tier of the coiling frame. Then the joints are welded by the automatic welding tractor. Then, through the auxiliary coil, the panel stretches to the lower tier, after which the joints are welded from the back side.

The quality control is then made: all welded joints are visually inspected and checked by an X-ray. For the work of the Non-destructive Control Laboratory under the lower tier of the coiling machine, staff access is specially provided. As a matter of fact, only the two-tiered coiling frame allows to really carry out quality control of welded joints in accordance with the requirements of Regulatory documents.

The quality of rolled tank structures, produced at the special facility, is sufficiently higher than that of the plates, “rolled” on the floor by the hauling winches. Our enterprise guarantees the exact geometric parameters, lack of deformation and ideal welding joints.

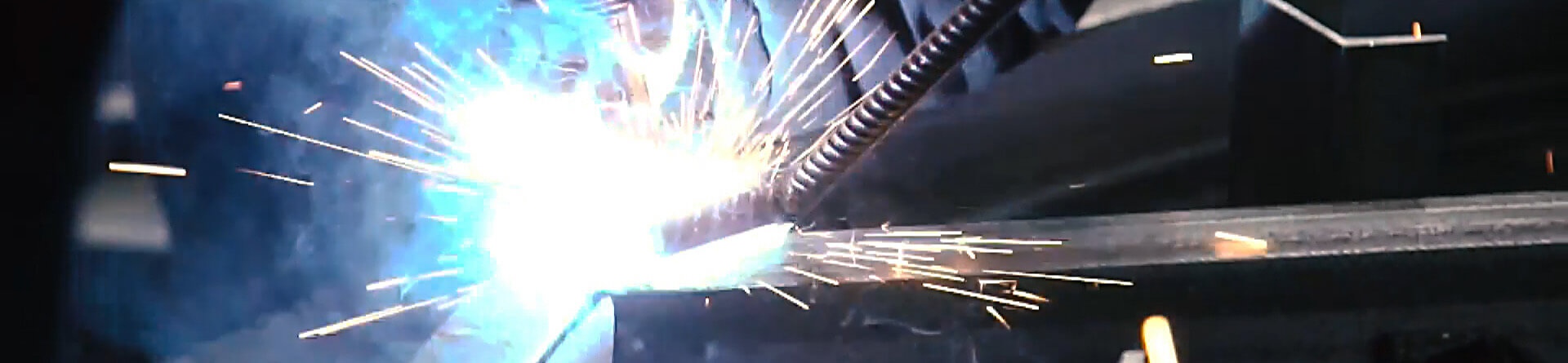

EuroTankWorks operates automatic and auto-manual Lincoln Electric and ESAB welding equipment.

Assembling of the tank elements is carried out at the columned welding keys in automatic regime. This provides high quality of assembling operations, making the period of steel tank fabrication shorter and decreasing the cost of manual work. Only few enterprises in Russia possess such kind of equipment, which makes our products competitive in quality.

Our company is one of the storage tanks manufacturers , having sufficient material and technical possibilities for appropriate metal-roll preparation, which ensures high quality of all tank elements.

Since a tank is not just a set of walls and bottom, but also manway plates, fitting pipes, flanges, footpaths and other technological elements, the quality of the final unit is greatly dependent on the accuracy of each element’s production.

Our enterprise has fully equipped mechanical metal processing shop, highly-accurate scarfing machines, plate-bending and plate-flattening equipment, metal turning lathes and drilling machines.

Two-tier mechanized Coiling Machine

Two-tier mechanized Coiling Machine

Welding of walls, bottoms and roofs of vertical steel tanks, carrying out X-ray and ultrasonic testing of welded joints, coiling of panels into a roll.

Parallel Planing and Milling Machine

Parallel Planing and Milling Machine

The reduction of sheet metal into the design size in width, ensuring its rectangularity, preparation of the edges for welding.

Underslung crane, load-carrying capacity 40t.

Underslung crane, load-carrying capacity 40t.

Moving of loads in the area of the Coiling Machine and in the zone of assembly of the shield structures of roofs. Shipment of large-sized finished products.

Underslung crane, load-carrying capacity 20t.

Underslung crane, load-carrying capacity 20t.

Moving of loads in all working zones of the workshop. Maintenance of assembly areas for auxiliary metal structures. Filling of containers with metal structures.

Layout of metal plates in the panel on the 2nd tier of the Coiling Machine

Gas-plasma cutting machine with program control

Gas-plasma cutting machine with program control

Cutting of sheet metal for manufacturing of billets of auxiliary metal structures.

Hydraulic guillotine shears 16x3200mm

Hydraulic guillotine shears 16x3200mm

Reduction of sheet metal in the design size along the length. Cutting of blanks.

Bending of prepared plates of the wall of the tank into the design radius (when the plate-by-plate manufacturing method is used).

Hydraulic profile bending machine

Hydraulic profile bending machine

Bending of angle, profile, beam and pipe into the design radius for manufacturing auxiliary metal structures.

Metal cutting during assembly of auxiliary metal structures.

Cutting the edges of plate metal at the project angle before welding

Welding tractor for automatic submerged arc welding ESAB

Welding tractor for automatic submerged arc welding ESAB

Welding of the wall, bottom and roof panels on the Coiling Machine

Semiautomatic welding machines ESAB Warrior 500i

Semiautomatic welding machines ESAB Warrior 500i

Welding of metal structures

To ensure the energy capacity of the Plant at a rate of 1000kVA.

Steel tanks fabrication facility EuroTankWorks is located in the workshop with a floor area of 5990 square meters and a ceiling height of 18m.

We have modernized the electrical system and now the power capacity of the Plant is 1000 k VA.

Our plant is gasified, which allows us to heat the working space with the modern infrared burners. This is a the obligatory condition providing the quality of welding in winter time. By the way, the majority of small tank manufacturers in Russia do not heat workshops and conduct welding operations at negative air temperatures, which is a violation of technical legislation.

Another important for the steel tank fabrication advantage of our workshop is the floor. Since before us in this shop the previous owners had assembled the aircraft, the floor is made of granite slabs on a thick concrete screed and it is perfectly flat. This simplifies the assembly of metal structures, and also allows to ensure the correct storage of sheet metal.